Scaling Up Carbon Removal: Climeworks' Partnership With Avantium

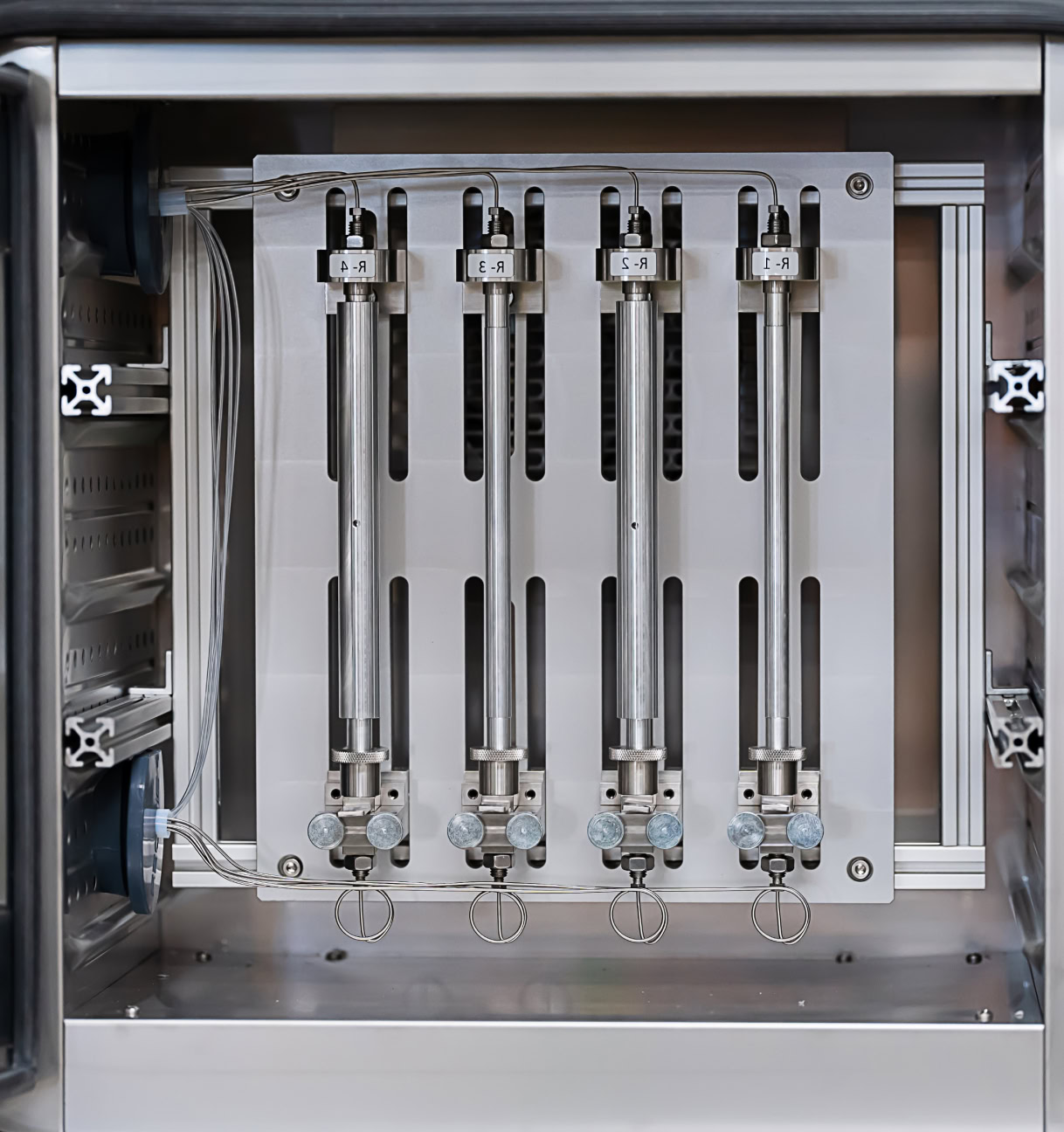

Climeworks is taking a big step in scaling up its direct air capture (DAC) technology through a partnership with Avantium R&D Solutions. The two companies are collaborating to refine CO2 adsorption processes, making DAC more efficient and cost-effective.The partnership focuses on the use of Avantium's high-throughput adsorption testing unit. This unit, which requires 25 times less sample material and gas, significantly reduces testing costs and improves accuracy. The result? Faster and more efficient development of DAC materials.

“This agreement enables us to take a significant step forward in building out a testing environment of industrial quality and expanding our high-quality supplier ecosystem,” said Jan Wurzbacher, Co-CEO and co-founder of Climeworks.

How the Partnership Works

The Avantium testing unit ensures that all CO2 capture materials are tested under the same conditions. This consistency enhances Climeworks' ability to refine its DAC technology. The unit also achieved a remarkable 98% uptime throughout 2024, making it highly reliable.

By enhancing testing processes, Climeworks can accelerate the deployment of its DAC systems globally. Its flagship project, the Mammoth plant in Iceland, is already making waves as the world’s largest DAC facility, capable of capturing up to 36,000 tonnes of CO2 annually.

The Challenge of DAC Costs

One of the biggest challenges in DAC technology is its high cost. Current systems operate at $500 to $1000 per tonne of CO2 captured. Climeworks aims to bring this down to $300 per tonne by 2030, but the industry benchmark is $100 per tonne.

David Webb, Chief Sustainability Officer at Boston Consulting Group, noted that bringing costs below $200 per tonne by 2050 is crucial. “This cost reduction would dramatically accelerate demand for DAC, encourage private developers to build more capacity, and make the technology affordable for the world,” he said.

>> In Other News: Transforming US Agriculture with Enhanced Weathering: A Path to Carbon Removal

Why Avantium's Testing Unit Matters

Avantium's unit is designed to enhance material efficiency and lower testing costs. The Amsterdam-based company, Avantium, is a leader in renewable and circular polymer materials. Its testing solutions are critical in helping Climeworks refine DAC systems.

Steven Olivier, Managing Director of Avantium R&D Solutions, expressed pride in the collaboration. “We take pride in our collaboration with Climeworks, a company that mirrors our dedication to sustainability and relentless innovation.” He added that the partnership reflects their commitment to scalable climate solutions.

Climeworks' Vision for the Future

Climeworks' DAC technology captures CO2 directly from the air and stores it underground in Iceland with its partner, Carbfix. The company's efforts are crucial in the fight against climate change.

The Mammoth plant, along with future projects, will benefit from the advanced testing capabilities provided by Avantium. This will help Climeworks reduce costs and enhance efficiency, making DAC a viable solution for large-scale carbon removal.

Avantium's Role in Sustainable Innovation

Avantium is known for developing technologies that convert plant-based sugars into sustainable plastics. Its expertise in chemical and material testing is now helping Climeworks advance DAC technology.

The company’s high-throughput adsorption testing unit is a game-changer. It allows Climeworks to test materials quickly and accurately, speeding up innovation in carbon removal.

The Road Ahead

The collaboration between Climeworks and Avantium is a significant step toward making DAC technology more affordable and scalable. As both companies continue to innovate, the goal of large-scale carbon removal becomes more achievable.

Climeworks' ambition to lower costs and scale up operations is supported by Avantium's cutting-edge testing solutions. Together, they are setting the stage for a future where DAC plays a critical role in reducing atmospheric CO2.

“This partnership is a testament to our shared commitment to addressing the urgent need for scalable climate solutions,” said Olivier.

With strong partnerships, innovative technology, and a clear vision, Climeworks and Avantium are leading the way in the fight against climate change.

Subscribe to the newsletter

Daily decarbonization data and news delivered to your inbox

Follow the money flow of climate, technology, and energy investments to uncover new opportunities and jobs.

Companies

Latest issues

-

What Do Submarines Have to Do With Hydrogen?

Inside This Issue 🚢 Hyundai Pitches Hydrogen Transport Tied To Canada Submarine Bid 🧱 The LEGO Group Expands Its Portfolio Of Carbon Removal Solutions 🏆 SAF Pioneer LanzaJet Honored With RFA Indus...

-

This $4.1M Deal Could Change Carbon Capture's Playbook

Inside This Issue 🗜️ CarbonQuest Lands $4.1M Alberta Deal on Gas Compressors 🛡️ CADO, 123Carbon, and Assure SAF Registry Join Forces to Tackle SAF Integrity Gaps ✈️ ISCC, OMV, and Airbus Partner t...

-

Can Koloma Crack Iowa's Billion-Year-Old Secret?

Inside This Issue ⛏️ Iowa's Hydrogen Rush: Can Koloma Strike Gold Before Rules Kick In? ✈️ Bentley Commits to Use 100% Sustainable Aviation Fuel for Car Airfreight 🌬️ Minister Parrott Provides Upd...

Company Announcements

-

CHIFENG, China, Feb. 27, 2026 /PRNewswire/ -- Envision Energy launched the first global shipment of green ammonia from Chifeng, Inner Mongolia to LOTTE Fine Chemical, a premier chemical company in ...

-

SAF Pioneer LanzaJet Honored With RFA Industry Award

Pioneering sustainable aviation fuel producer LanzaJet received the Renewable Fuels Association’s 2026 Industry Award at the National Ethanol Conference in Orlando this week. Last year the company ...

-

Houston Hosts World Hydrogen North America 2026 Industry Gathering

Hydrogen is one of the energy sources that has evolved the most when it comes to how developers plan and execute projects. The main reason for this is the advanced technology that has penetrated th...

-

Trump EPA Eyes Reallocating Waived Biofuel Obligations To Refiners: Report

The question of whether to reallocate those exempted blending obligations to larger refiners is a point of contention between the agriculture and fuel industries The Trump administration has settl...