Cascade Biocatalysts Secures $2.6 M to Scale Enzymes for Biomanufacturing

Published by Todd Bush on August 22, 2023

August 22, 2023 09:13 AM Eastern Daylight Time

DENVER--(BUSINESS WIRE)--Cascade Biocatalysts, a biomanufacturing company catalyzing green chemistry, raised an oversubscribed $2.6 M pre-seed led by Ten VC with participation from mplify.LA, Boost VC, Range Ventures, Spacecadet, and the Cool Climate Collective. Cascade aims to use the raised funds to scale its impact from the lab bench to pilot scale and to support its initial wave of customers.

Cascade's co-founders: Alex Rosay (CEO, left) and James Weltz (CSO, right)

Cascade’s vision is to make the industrial use of enzymes more affordable to accelerate the transition to greener chemical manufacturing. At the heart of Cascade Biocatalysts' breakthrough lies its proprietary technology, the patent-pending Body Armor for Enzymes™, which drives more cost-effective and sustainable chemical reactions by improving enzyme performance.

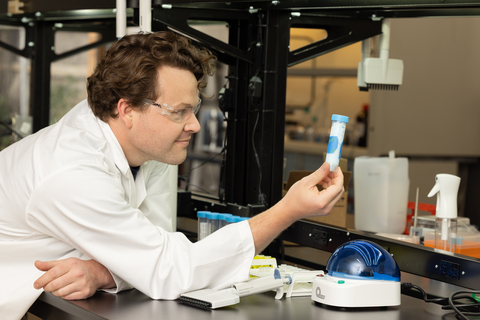

The inventor and his creation: James Weltz, Cascade's CSO, with his novel enzyme immobilization solution

For billions of years, nature has relied on enzymes to efficiently make useful molecules. Cascade is moving nature's catalysts out of the cell and into the factory, transitioning chemical manufacturing away from energy-intensive, petrochemical-based processes. By doing so, the company aims to address the three gigatons of greenhouse gas emissions generated by the chemicals industry. Overcoming the current barrier of enzyme cost is a crucial step toward making this a reality.

Cascade’s technology uses readily available and cost-effective materials to keep expensive enzymes lasting significantly longer. So far, Cascade has worked on 15 different enzymes and is 100% successful at improving stability under tough industrial conditions, including for multiple paying customers at the lab scale. Find more data in this article that highlights Cascade’s potential in creating molecular factories. The company's initial projects span diverse applications, including carbon dioxide capture, fragrance manufacturing, and wastewater treatment, highlighting the broad commercial potential of biocatalysts.

The company's co-founders, Alex Rosay and James Weltz, bring together chemical engineering backgrounds, industry expertise, and scientific innovation.

James invented the technology while doing his PhD in the field of enzyme immobilization. “I had tried all other solutions, and they were inconsistent,” said James Weltz, Cascade’s Chief Scientific Officer (CSO). “When I developed our novel approach, I transformed immobilizing enzymes from a trial-and-error process into an engineering discipline.”

“From the moment I met James, I knew his technology would revolutionize biomanufacturing,” said Alex Rosay, CEO and industry veteran. “From my time as a product manager at Zymergen, I saw a billion dollars go towards precision fermentation unsuccessfully, and I realized cell-free and enzyme processes were the future of the industry, though too expensive today. James’s technology solves this.”

With its headquarters in Denver and a presence in California and New York, Cascade Biocatalysts is well-positioned to spearhead the cell-free biomanufacturing revolution. Interested parties can contact Alex Rosay at [email protected] to learn more.

>> In Other News: Astronergy, NIO and OPF hand for the world's first EV PV Self-consumption System with V2G Chargers at Qilian Mountain National Park

About Cascade Biocatalysts

Cascade Biocatalysts specializes in advancing enzyme-based processes. With its groundbreaking Body Armor for Enzymes™ technology, the company seeks to drive greener and more cost-effective chemical reactions, reducing greenhouse gas emissions and promoting sustainability across industries. Headquartered in Denver, Cascade is committed to scaling up its impact and revolutionizing the future of the chemical economy.

Subscribe to the newsletter

Daily decarbonization data and news delivered to your inbox

Follow the money flow of climate, technology, and energy investments to uncover new opportunities and jobs.

Latest issues

-

Can Koloma Crack Iowa's Billion-Year-Old Secret?

Inside This Issue ⛏️ Iowa's Hydrogen Rush: Can Koloma Strike Gold Before Rules Kick In? ✈️ Bentley Commits to Use 100% Sustainable Aviation Fuel for Car Airfreight 🌬️ Minister Parrott Provides Upd...

-

$47M Just Poured Into This SAF Producer

Inside This Issue 💰 LanzaJet Announces $47M in New Capital and First Close of Equity Round at $650M Pre-Money Valuation 🚢 Maersk's Ethanol Bet Could Reshape U.S. Fuel Markets 🪨 Canada Nickel and t...

-

Kita's $29M Bet Signals Carbon Insurance Is Here

Inside This Issue 🛡️ Kita's $29M Bet Signals Carbon Insurance Is Here 🏗️ CCI BioEnergy Selects Arcadis As Design-Engineer Partner Under Master Service Agreement 🤝 Tapestry and Climeworks Announce ...

Company Announcements

-

Climeworks Establishes Canadian Headquarters in Calgary

Calgary, Alberta, February 20, 2026 — Climeworks, a global leader in commercial carbon removal, has established its Canadian headquarters at Calgary’s ETC, one of Alberta’s leading hubs where start...

-

MIAMI, Feb. 24, 2026 /CNW/ - Power Sustainable Infrastructure Credit ("PSIC") recently closed an $85M senior secured financing for Sagepoint Energy ("Sagepoint"), a vertically integrated renewable ...

-

HALIFAX, NS, Feb. 24, 2026 /CNW/ - The Nova Scotia Salmon Association (NSSA) is celebrating a significant advancement in climate action and watershed restoration as Royal Bank of Canada purchases a...

-

Honeywell International: Process Technology to Help Verso Energy Accelerate eSAF Production

CHARLOTTE, N.C., Feb. 24, 2026 - Honeywell today announced that Verso Energy, an integrated energy company focused on producing low-carbon molecules, will use Honeywell UOP's eFiningTM methanol-to-...