The overlooked path to hydrogen leadership: natural gas

Hydrogen’s buzz isn’t slowing down. But the real energy play might surprise some folks—it’s not solar panels or wind farms. It’s natural gas, especially when paired with carbon capture. And ExxonMobil is betting big on it.

While headlines scream about clean hydrogen, the truth is, most of the world’s hydrogen still comes from steam methane reforming (SMR)—a process using natural gas. In fact, over 95% of global hydrogen is made this way. The U.S. is already producing around 10 million metric tons annually, and thanks to domestic gas abundance, it’s doing it at scale.

This isn't about clinging to the past. It's about recognizing what already works—and using it to lead.

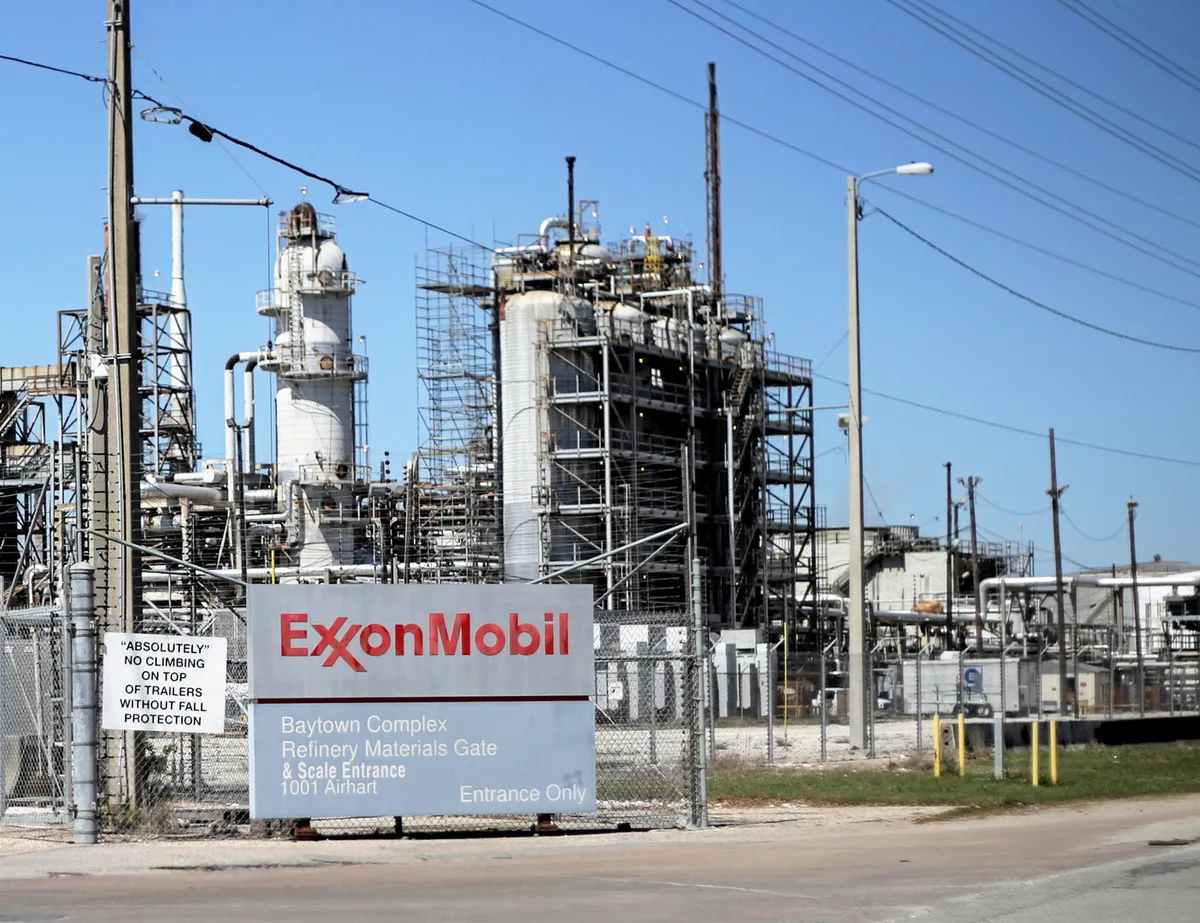

Baytown: A bold move by ExxonMobil

Let’s talk scale. Over in Texas, ExxonMobil is building something huge at its Baytown facility. If completed, it could become the largest low-carbon hydrogen plant in the world. The plan? Produce 1 billion cubic feet of hydrogen per day and capture 10 million metric tons of CO₂ annually.

That’s not a prototype. It’s a working model of how the U.S. could power industrial sectors—like steel and shipping—without waiting decades for green hydrogen tech to catch up.

But it hinges on one thing: policy support. Specifically, the 45V tax credit, part of the Inflation Reduction Act. According to Darren Woods, CEO of ExxonMobil, “Without 45V locked in, the facility won’t move forward.” That’s not a bluff. It’s economics.

>> RELATED: Ammonia Offtake, Advancing the World’s Largest Low-Carbon Hydrogen Project

Why natural gas still matters

Critics call it dirty. But U.S. natural gas is some of the cleanest on the planet, thanks to methane leak controls and strict regulations. Plus, it’s abundant and cheap—two words energy execs love.

Unlike China or the UAE, the U.S. doesn't have to worry about supply chains or foreign imports. It has everything it needs right at home. And when you add CCS into the mix, blue hydrogen becomes a low-emission, scalable solution—not just a placeholder.

The International Energy Agency even noted in 2023 that “blue hydrogen will be critical to meeting global decarbonization goals in hard-to-electrify sectors.”

America’s secret weapon: infrastructure

Here’s something most people don’t know. The U.S. already has more than 1,600 miles of hydrogen pipelines, mostly along the Gulf Coast. That’s infrastructure other countries are still dreaming of.

And it’s not just pipelines. America’s industrial know-how, workforce, and CCS expertise—built from decades in oil and gas—gives it a massive head start.

So while Australia experiments with electrolysis, and China doubles down on coal-heavy hydrogen, the U.S. could win the race simply by doing more of what it already knows how to do.

The global race is heating up

Hydrogen isn’t just a climate story anymore. It’s a trade story.

By 2050, Europe, Japan, and South Korea are expected to import over 50 million metric tons of hydrogen per year. These countries aren’t just looking for fuel—they want data-backed, transparent, low-carbon options. America can offer that.

South Korea’s Hydrogen Economy Roadmap highlights a strong demand for blue hydrogen imports starting this decade.

If the U.S. moves fast, hydrogen could become the next liquefied natural gas (LNG) moment—another major export boom.

/https://static.texastribune.org/media/images/ExxonMobileSign.jpg)

>> In Other News: Anaergia and Capwatt Sign Binding Letter of Intent for Nine New Biogas Plants in Europe

Three reasons America can lead

1. Domestic natural gas advantage

The shale revolution made natural gas cheap, reliable, and secure. No other country can match this mix of price and control. With massive reserves and decades of production experience, the U.S. has the upper hand in cost and supply chain stability. It’s also less vulnerable to the geopolitical risks that plague other energy sources—a huge plus in today’s uncertain global climate.

2. Existing hydrogen infrastructure

From Gulf Coast pipelines to Baytown’s planned output, the U.S. already has the bones of a global hydrogen leader. This head start means less time spent building from scratch—and more time producing, moving, and exporting hydrogen at scale. That infrastructure isn’t just pipes and plants—it’s also the trained workforce and regulatory familiarity that other countries are still trying to develop.

3. Policy levers like the 45V tax credit

Getting 45V right could unlock billions in hydrogen investment. Without it, projects stall, and rivals move in. It’s a make-or-break incentive that signals whether America is serious about clean energy leadership. If implemented well, it could trigger a wave of new projects across the country—fueling job growth, emissions reductions, and a competitive edge in global trade.

Don’t wait—scale now

While the world waits for green hydrogen costs to drop, blue hydrogen can scale today. It’s not perfect, but it’s practical.

If the U.S. acts now—supporting CCS, easing permitting for plants and pipelines, and aggressively promoting exports—it could lead the hydrogen economy for decades.

But that window? It won’t stay open forever.

The Next Move Is Ours

Baytown isn’t just a hydrogen plant. It’s a message. It says the U.S. doesn’t need to reinvent the wheel to lead in clean energy. It just needs to use what it already has—and use it smartly.

The global hydrogen game is on. And if the U.S. plays its cards right, it won’t just participate—it’ll dominate.

Subscribe to the newsletter

Daily decarbonization data and news delivered to your inbox

Follow the money flow of climate, technology, and energy investments to uncover new opportunities and jobs.

Companies

Latest issues

-

Can Koloma Crack Iowa's Billion-Year-Old Secret?

Inside This Issue ⛏️ Iowa's Hydrogen Rush: Can Koloma Strike Gold Before Rules Kick In? ✈️ Bentley Commits to Use 100% Sustainable Aviation Fuel for Car Airfreight 🌬️ Minister Parrott Provides Upd...

-

$47M Just Poured Into This SAF Producer

Inside This Issue 💰 LanzaJet Announces $47M in New Capital and First Close of Equity Round at $650M Pre-Money Valuation 🚢 Maersk's Ethanol Bet Could Reshape U.S. Fuel Markets 🪨 Canada Nickel and t...

-

Kita's $29M Bet Signals Carbon Insurance Is Here

Inside This Issue 🛡️ Kita's $29M Bet Signals Carbon Insurance Is Here 🏗️ CCI BioEnergy Selects Arcadis As Design-Engineer Partner Under Master Service Agreement 🤝 Tapestry and Climeworks Announce ...

Company Announcements

-

Climeworks Establishes Canadian Headquarters in Calgary

Calgary, Alberta, February 20, 2026 — Climeworks, a global leader in commercial carbon removal, has established its Canadian headquarters at Calgary’s ETC, one of Alberta’s leading hubs where start...

-

MIAMI, Feb. 24, 2026 /CNW/ - Power Sustainable Infrastructure Credit ("PSIC") recently closed an $85M senior secured financing for Sagepoint Energy ("Sagepoint"), a vertically integrated renewable ...

-

HALIFAX, NS, Feb. 24, 2026 /CNW/ - The Nova Scotia Salmon Association (NSSA) is celebrating a significant advancement in climate action and watershed restoration as Royal Bank of Canada purchases a...

-

Honeywell International: Process Technology to Help Verso Energy Accelerate eSAF Production

CHARLOTTE, N.C., Feb. 24, 2026 - Honeywell today announced that Verso Energy, an integrated energy company focused on producing low-carbon molecules, will use Honeywell UOP's eFiningTM methanol-to-...