Hyosung: Newly Transformative Nylon, As Core Material for Hydrogen Energy

Published by Todd Bush on September 29, 2022

September 28, 2022 09:00 AM Eastern Daylight Time SEOUL, South Korea--(BUSINESS WIRE)--Nylon has evolved into the core material of the hydrogen energy industry.

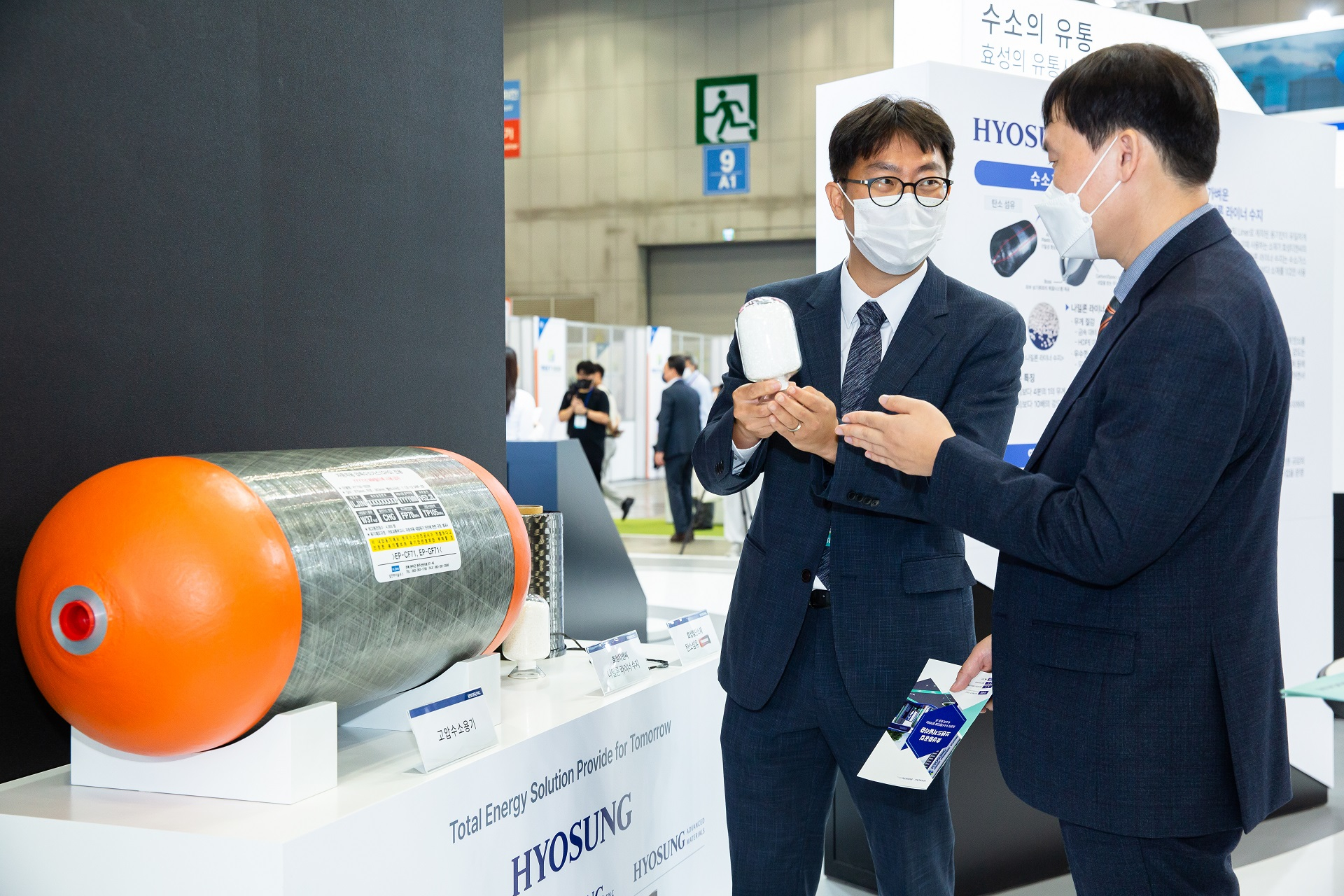

Hyosung TNC (KRX:298020) announced on the 7th that it has succeeded in developing and using nylon for the liner material of hydrogen vehicle fuel tanks with its own technology, the first of its kind for a Korean company.

A liner is a core component required to store hydrogen in the fuel tank's internal container and prevent leakage.

Hyosung TNC's nylon material is superior to conventional metal and high-density polyethylene (HDPE) liner materials in terms of lightweight, gas barrier, and impact resistance.

Superior light and safe than metal… Excellent impact resistance against temperature fluctuation

The nylon liner material developed by Hyosung TNC is 70% lighter than metal and 50% lighter than HDPE and gas barrier property that prevents leakage of hydrogen gas is also 30% higher than metal and 50% higher than HDPE.

Metal liner is heavy and has a high risk of brittleness when exposed to hydrogen for a long period of time, whereas nylon liner has low hydrogen absorption and air permeability, so there is no risk of being brittleness.

HDPE liners are used as high-pressure containers at 400bar levels, but cannot withstand the 700bar pressure required by typical hydrogen electric vehicles.

In addition, the hydrogen container liner must be able to withstand rapidly changing temperature fluctuation caused by frequent charging and discharging of hydrogen and the nylon liner has excellent impact resistance against to it from -40 to 85 degrees Celsius.

Expected the import effect of 270 billion won annually by 2030

The success of this development is significant in that it has laid the foundation for Hyosung TNC to enter the nylon liner market, which has been monopolized by foreign companies, for the first time as a domestic company.

According to H2 Research, a research institute specializing in the hydrogen market, the global hydrogen vehicle market will grow in earnest, including restrictions on the operation of internal combustion engine trucks in major urban areas in Europe from 2025 is expected to expand to 1.05 million units.

Therefore, the import substitution effect of the nylon material liner market is expected to grow to about 270 billion won annually in 2030.

In addition, with the expansion of various hydrogen mobility markets such as hydrogen electric vehicles, drones, trams, ships, and UAM (urban air mobility), nylon is expected to gain more attention as a liner material for hydrogen containers.

The complete of Hydrogen Value Chain in Production, Distribution, Storage and Utilization

The nylon liner is expected to contribute to the completion of Hyosung's hydrogen value chain.

Hyosung has built a hydrogen value chain through No. 1 supplier of hydrogen charging stations in Korea, construction of liquefied hydrogen plants and liquefied hydrogen filling stations that will change the map of the hydrogen economy, production of carbon fiber, which is essential for fuel tanks for hydrogen vehicles, etc.

The success of this development is significant because Hyosung has secured the technological capabilities to lead the global market not only in the production and distribution of hydrogen but also in the storage and utilization fields.

Chairman Cho Hyun-Joon, 'Fiber evolves into a key energy material by combining to technology'

Hyosung TNC's nylon-applied hydrogen container passed the hydrogen container international quality standard (UN/ECE R134) in June, and has been equipped with function, quality and technical perfection as a liner material. It is also planned to conduct commercial tests in cooperation with hydrogen fuel tank manufacturers and automakers.

Hyosung TNC is planning to expand the application of nylon as a liner material from tube trailers of commercial trucks to CNG and hydrogen vessels sailing the seas around the world, such as Antarctica and the Equator, by enhancing the impact and heat resistance range from -60 to 90 degrees Celsius.

In addition, as Hyosung TNC developed the world's first recycled nylon fiber technology from recycled fishing nets discarded in the sea, it plans to expand the eco-friendly plastic material market by applying recycled nylon to a liner material in the future.

Chairman Cho Hyun-Joon said, 'Hyosung TNC's development of nylon liner material demonstrates, even in the textile industry, which has been regarded as a declining industry, the innovation that transforms it into a key material for the high-tech hydrogen industry, can happen if it's supported by technology. We will contribute to the development of the future eco-friendly energy industry with the technology of materials and textiles.'

Subscribe to the newsletter

Daily decarbonization data and news delivered to your inbox

Follow the money flow of climate, technology, and energy investments to uncover new opportunities and jobs.

Latest issues

-

96% Pure H₂ Found Underground — Now What?

Inside This Issue 🧪 HyTerra's Kansas H₂ Could Power a Historic Industry First 🤝 Prime Minister Carney Secures Ambitious New Partnership With India Focused on Energy, Talent, and Technology Françai...

-

What Do Submarines Have to Do With Hydrogen?

Inside This Issue 🚢 Hyundai Pitches Hydrogen Transport Tied To Canada Submarine Bid 🧱 The LEGO Group Expands Its Portfolio Of Carbon Removal Solutions 🏆 SAF Pioneer LanzaJet Honored With RFA Indus...

-

This $4.1M Deal Could Change Carbon Capture's Playbook

Inside This Issue 🗜️ CarbonQuest Lands $4.1M Alberta Deal on Gas Compressors 🛡️ CADO, 123Carbon, and Assure SAF Registry Join Forces to Tackle SAF Integrity Gaps ✈️ ISCC, OMV, and Airbus Partner t...

Company Announcements

-

Plug Power Welcomes Jose Luis Crespo as Chief Executive Officer

Crespo’s commercial and operational expertise positions Plug for disciplined growth and execution SLINGERLANDS, N.Y., March 03, 2026 (GLOBE NEWSWIRE) -- Plug Power Inc. (NASDAQ: PLUG), a global le...

-

Company expands global footprint through signed feedstock MOUs intended to support the future development of up to 1,000,000 tons of annual SAF production by 2035 HOUSTON, March 3, 2026 /PRNewswir...

-

Leading Institutional Investor Backs Over 650 MW Wind Portfolio, Integrated Green Fuels Developments, and Multi-GW Renewables Pipeline EverWind today announced a US$175 million (CAD$240 million) s...

-

Murkowski And Colleagues Introduce Bipartisan Bill To Advance Marine Carbon Dioxide Removal

Washington, D.C. – Today, U.S. Senators Lisa Murkowski, (R-AK) and Brian Schatz, (D-HI), with Representatives Suzanne Bonamici, (D-OR) and Earl L. “Buddy” Carter, (R-GA) introduced bipartisan, bica...