MHI Awarded Contract for Basic Design of Japan's Largest CO₂ Capture Plant at Hokkaido Electric Power's Tomato-Atsuma Power Station -- One of Advanced CCS Projects in Japan, Moving Forward toward the Realization of a Carbon-Neutral World

Published by Todd Bush on July 9, 2025

Investigation of the facility's main equipment and specifications for capture of 5,200 tons of CO2 per day through MHI's proprietary CO2 capture technology

Concept to store captured CO2 in the sea area off Tomakomai, based on JOGMEC's advanced CCS projects

Hokkaido Electric Power's Tomato-Atsuma Power Station(Photo Courtesy of Hokkaido Electric Power Co., Inc.)

Tokyo - Mitsubishi Heavy Industries, Ltd. (MHI) has received an order from Hokkaido Electric Power Co., Inc. (HEPCO) for the basic design of a CO2 capture plant (Front End Engineering Design, FEED) for the company's Tomato-Atsuma Power Station. The plant will have the capacity to capture 5,200 tons of CO2 per day from the flue gases emitted during combustion of the boilers in the power station. For this FEED project, MHI will investigate the main equipment and specifications through MHI's proprietary CO2 capture technology, in preparation for the introduction of equipment in the future. When completed, the facility is expected to be the largest CO2 capture plant in Japan.

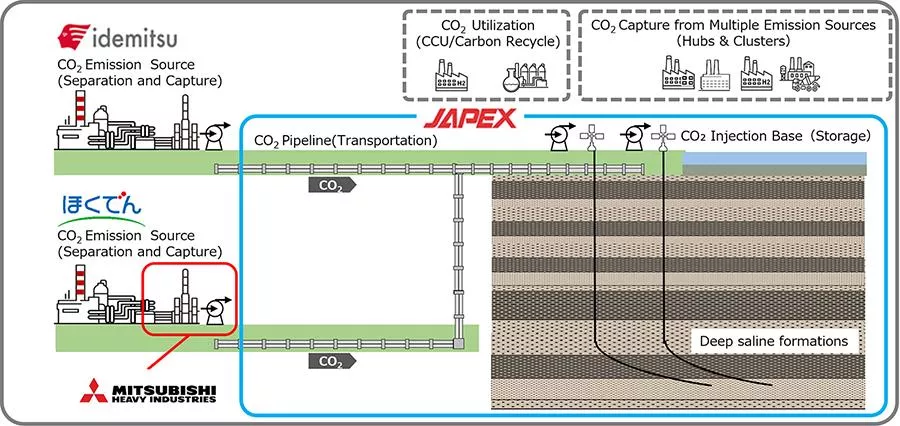

HEPCO, in cooperation with Idemitsu Kosan Co., Ltd. and Japan Petroleum Exploration Co., Ltd., concluded a contract with the Japan Organization for Metals and Energy Security (JOGMEC), a Japanese government Incorporated Administrative Agency, for the design work of a CCS (Note 1) project in the Tomakomai area of Hokkaido, based on an open call for business consignment regarding "Engineering Design for Japanese Advanced CCS Projects." (Note 2) According to the agreement, the conception for the project is for CO2 captured at HEPCO's Tomato-Atsuma Power Station to be stored in deep saline formations in the Tomakomai area, with the aim of storing approximately 1.5 million to 2 million tons of CO2 per year by 2030. Of note, Japan's Ministry of Economy, Trade and Industry (METI) has selected a sea area near Tomakomai as Japan's first "specified area" under the Act on Carbon Dioxide Storage Business ("CCS Business Act"), and exploratory drilling is currently being considered.

MHI Group has formally declared its commitment to achieving carbon neutrality by 2040 (MISSION NET ZERO), and the Company is now working strategically to decarbonize both the energy demand and supply sides. A core element of the Company's "Energy Transition," which targets decarbonization on the energy supply side, is the development of a carbon capture, utilization and storage (CCUS) value chain integrating diverse sources of carbon emissions with modes for carbon storage and utilization. Going forward, MHI Group will continue to proactively promote its CCUS business worldwide, applying its proprietary CO2 capture technologies, contributing as a solutions provider to reducing greenhouse gas emissions on a global scale, and developing further solutions that contribute to environmental protection.

(Note 1) Carbon dioxide Capture and Storage.

(Note 2) For more information on the CCS project in the Tomakomai area under the JOGMEC "Advanced CCS Project" public offering, see the following press release (Japanese): https://www.hepco.co.jp/info/2024/1252632\_2023.html

Image of the Overall Scope of the Project

>> In Other News: Cenntro Develops Second-Generation Hydrogen Fuel Cell Class 8 Semi-Tractor and Receives EPA Certification

About MHI Group's CO2 capture technologies

MHI Group has been developing the "KM CDR Process™" (Kansai Mitsubishi Carbon Dioxide Recovery Process) and the "Advanced KM CDR Process™" in collaboration with the Kansai Electric Power Co., Inc. since 1990. As of July 2025, the Company has delivered 18 plants adopting these processes. The Advanced KM CDR Process™ adopts the "KS-21™" solvent, which incorporates technological improvements over the amine-based "KS-1™" and offers superior regeneration efficiency and lower deterioration than the KS-1™, and it has been verified to provide excellent energy saving performance, reduce operation costs, and result in low amine emissions.

Further information on MHI Group's CO2 capture plants:https://www.mhi.com/products/engineering/co2plants.html

Subscribe to the newsletter

Daily decarbonization data and news delivered to your inbox

Follow the money flow of climate, technology, and energy investments to uncover new opportunities and jobs.

Latest issues

-

This $4.1M Deal Could Change Carbon Capture's Playbook

Inside This Issue 🗜️ CarbonQuest Lands $4.1M Alberta Deal on Gas Compressors 🛡️ CADO, 123Carbon, and Assure SAF Registry Join Forces to Tackle SAF Integrity Gaps ✈️ ISCC, OMV, and Airbus Partner t...

-

Can Koloma Crack Iowa's Billion-Year-Old Secret?

Inside This Issue ⛏️ Iowa's Hydrogen Rush: Can Koloma Strike Gold Before Rules Kick In? ✈️ Bentley Commits to Use 100% Sustainable Aviation Fuel for Car Airfreight 🌬️ Minister Parrott Provides Upd...

-

$47M Just Poured Into This SAF Producer

Inside This Issue 💰 LanzaJet Announces $47M in New Capital and First Close of Equity Round at $650M Pre-Money Valuation 🚢 Maersk's Ethanol Bet Could Reshape U.S. Fuel Markets 🪨 Canada Nickel and t...

Company Announcements

-

RCJY and Climeworks Deepen Partnership to Advance Large-scale Direct Air Capture in Saudi Arabia

Key takeaways: Under the guidance of the Ministry of Energy, the Royal Commission for Jubail and Yanbu and Climeworks have signed a Memorandum of Understanding to expand their collaboration on de...

-

CHARBONE Confirms New UHP Hydrogen Orders and its First UHP Oxygen Order in the United States

Brossard, Quebec, February 25, 2026 – CHARBONE CORPORATION (TSXV: CH; OTCQB: CHHYF; FSE: K47) (“CHARBONE” or the “Company”), a North American producer and distributor specializing in clean Ultra Hi...

-

Climeworks Establishes Canadian Headquarters in Calgary

Calgary, Alberta, February 20, 2026 — Climeworks, a global leader in commercial carbon removal, has established its Canadian headquarters at Calgary’s ETC, one of Alberta’s leading hubs where start...

-

MIAMI, Feb. 24, 2026 /CNW/ - Power Sustainable Infrastructure Credit ("PSIC") recently closed an $85M senior secured financing for Sagepoint Energy ("Sagepoint"), a vertically integrated renewable ...