Low-carbon hydrogen is emerging as a crucial player in the battle against climate change. By providing a cleaner energy source, it holds the potential to significantly reduce global greenhouse gas emissions. Enter Aurora Hydrogen, an Edmonton-based technology company, which is making strides with its innovative methane pyrolysis technology. This article delves into how Aurora Hydrogen, bolstered by recent funding, is poised to revolutionize hydrogen production and drive us toward a net-zero future.

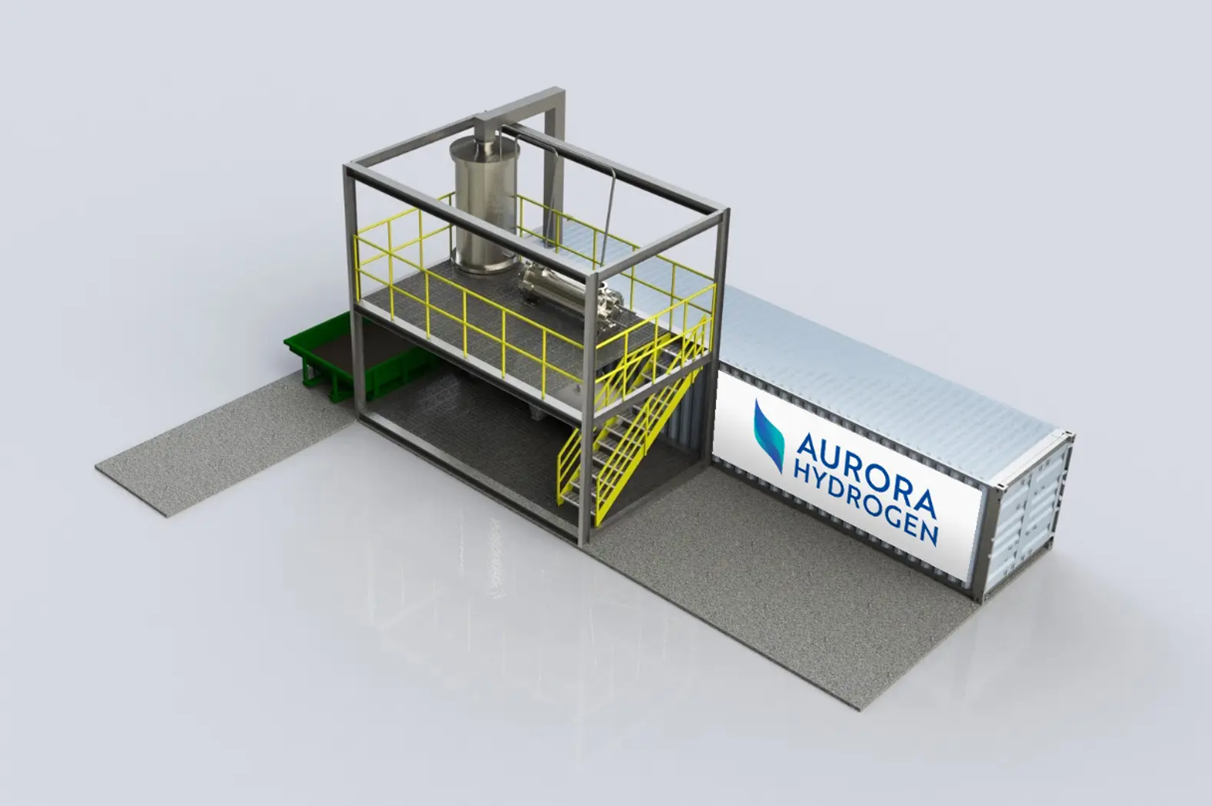

Aurora Hydrogen’s Methane Pyrolysis Technology

Methane pyrolysis is a process that transforms methane into hydrogen and solid carbon, without emitting carbon dioxide. This method stands out because it produces hydrogen in a low-carbon, cost-effective manner. Aurora Hydrogen’s technology takes advantage of this process, offering a significant improvement over traditional hydrogen production methods, which often involve high emissions and greater costs.

Aurora’s system efficiently converts methane into hydrogen and solid carbon, requiring no water and generating no emissions. This not only makes the hydrogen production process greener but also ensures it is economically viable for widespread use. The result is a clean, low-cost hydrogen that can be produced at the point of use, eliminating the need for transportation or CO2 storage.

The Funding Boost: A Game Changer

The recent funding awards are set to be a game changer for Aurora Hydrogen. The company received $3 million from Natural Resources Canada (NRCan) and over $1 million from the NGIF Accelerator. This financial support is aimed at scaling and commercializing Aurora’s methane pyrolysis technology.

With these funds, Aurora plans to enhance its Technology Readiness Level, moving closer to full-scale deployment. The funding will support efforts to pilot and commercialize the technology, ensuring it can meet the market’s demand for low-cost, clean hydrogen. This development is crucial for engaging with government programs and compliance markets, as well as the voluntary carbon market (VCM).

>> In Other News: How Summit Carbon Solutions and Mangrove Systems Are Revolutionizing Carbon Removal Projects

Impact on Industrial Decarbonization

Aurora Hydrogen’s technology promises a significant impact on industrial decarbonization, particularly in hard-to-decarbonize sectors. Industries that rely heavily on chemical fuels and emit high levels of CO2 can benefit immensely from this innovation.

For instance, sectors like steel production, cement manufacturing, and chemical processing, which are traditionally challenging to decarbonize, can use Aurora’s clean hydrogen to reduce their carbon footprints. By integrating this technology, these industries can achieve significant emissions reductions, making a substantial contribution to global climate goals.

Broader Implications for a Net-Zero Economy

Scaling low-carbon hydrogen production is a vital step towards achieving a net-zero economy. Aurora Hydrogen’s efforts align with broader strategies to combat climate change, both within Canada and globally. The company’s technology supports the Hydrogen Strategy for Canada, which aims to position the country as a global leader in clean energy.

Moreover, Aurora’s advancements contribute to global efforts to reduce emissions and promote sustainable growth. As the technology matures and becomes more widely adopted, it could spur further innovations and developments in the clean energy sector, paving the way for a more sustainable future.

Voices of Innovation: Key Quotes

Andrew Gillis, CEO, Aurora Hydrogen, emphasized the importance of this funding: “We’re honored to have been selected by NRCan and NGIF Accelerator for this funding, which we see as a testament to the enthusiasm and demand for our hydrogen solution. With this support, we’ll be able to scale our hydrogen production technology to provide the market with the lowest-cost clean hydrogen — a key step in bringing a net-zero economy to life.”

John Adams, President and CEO of NGIF Accelerator, shared his excitement: “I am excited to support Aurora Hydrogen's efforts to scale hydrogen production through their methane pyrolysis technology. This funding underscores our commitment to accelerating clean technology solutions that reduce global emissions.”

Paving the Way for the Future

Aurora Hydrogen’s innovative approach to hydrogen production marks a significant step forward in the clean energy landscape. By leveraging the capabilities of methane pyrolysis, Aurora is not only making hydrogen production more efficient and sustainable but also setting a precedent for future clean energy technologies.

The transformative potential of this technology extends beyond immediate applications. As Aurora continues to develop and expand its projects, the broader implications for industrial decarbonization and global climate efforts become increasingly clear. This partnership and the ensuing advancements underscore the critical role of innovation and collaboration in achieving a net-zero future. Aurora Hydrogen is indeed paving the way for a greener, more sustainable world.

Subscribe to the newsletter

Daily decarbonization data and news delivered to your inbox

Follow the money flow of climate, technology, and energy investments to uncover new opportunities and jobs.

Latest issues

-

Kita's $29M Bet Signals Carbon Insurance Is Here

Inside This Issue 🛡️ Kita's $29M Bet Signals Carbon Insurance Is Here 🏗️ CCI BioEnergy Selects Arcadis As Design-Engineer Partner Under Master Service Agreement 🤝 Tapestry and Climeworks Announce ...

-

Cummins Quit Electrolyzers. Electric Hydrogen Didn't.

Inside This Issue ⚡ Cummins Quit Electrolyzers. Electric Hydrogen Didn't. 🧪 New Electrified Method Captures Carbon Dioxide From Air 🌾 Iowa Could Be on the Cusp of a Hydrogen Rush; Lawmakers Weigh ...

-

Inside America’s Carbon Capture Reality Check

Inside This Issue ⚡ Duke Energy Florida Goes Live With First 100% Hydrogen System ✈️ Air bp Signs Agreement With Airbus on Flight Services and Fuel Supplies in Europe 🌊 Pairing Reefs and Mangroves...

Company Announcements

-

Vancouver, British Columbia--(Newsfile Corp. - February 18, 2026) - Element One Hydrogen & Critical Minerals Corp. (CSE: EONE) ("Element One" or the "Company") is pleased to announce the format...

-

CCI BioEnergy Selects Arcadis As Design-Engineer Partner Under Master Service Agreement

First project under the agreement will contribute to doubling the processing capacity of Toronto’s Disco Road Organic Processing Facility Toronto, ON – Arcadis (EURONEXT: ARCAD) is pleased to anno...

-

QIMC Reports Diamond Drilling Underway at West Advocate Hydrogen Project, Nova Scotia

Montreal, Quebec-- Québec Innovative Materials Corp. QIMC (OTCQB: QIMCF) (FSE: 7FJ) ("QIMC" or the "Company") announces that diamond drilling operations commenced on February 17, 2026, at its West ...

-

Seaweed Farming Could Remove Millions of Tons of CO₂ Each Year, Study Finds

Seaweed farming is a key strategy for carbon dioxide removal (CDR), offering both climate mitigation and ecological benefits. A recent study published in Communications Sustainability examined how ...