Turning Carbon Dioxide Into Fuel Just Got Easier, Thanks to Acid Bubbles

Published by Todd Bush on June 13, 2025

A team of researchers at Rice University have discovered a surprisingly simple method for vastly improving the stability of electrochemical devices that convert carbon dioxide into useful fuels and chemicals, and it involves nothing more than sending the CO₂ through an acid bubbler.

Their study, published in Science, addresses a major bottleneck in the performance and stability of CO₂ reduction systems: the buildup of salt that clogs gas flow channels, reduces efficiency and causes the devices to fail prematurely. Using a technique they call acid-humidified CO₂, the researchers extended the operational life of a CO₂ reduction system more than 50-fold, demonstrating more than 4,500 hours of stable operation in a scaled-up reactor — a milestone for the field.

>> In Other News: US Senate Should Ease Provisions for Clean-energy Tax Credits, Republican Senator Says

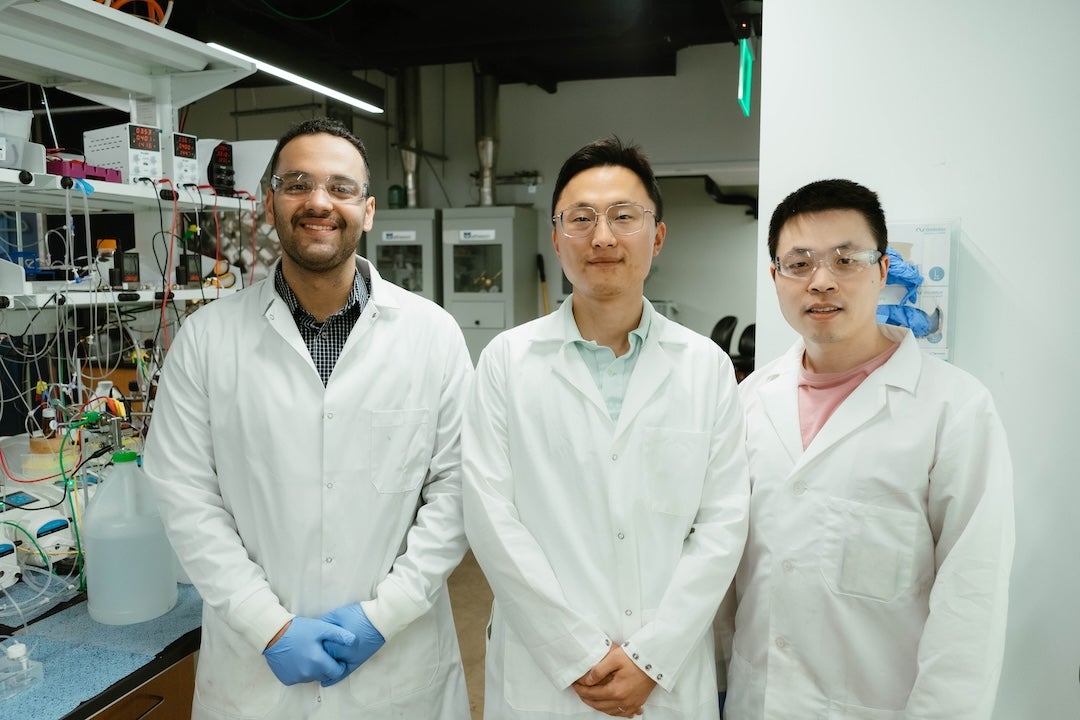

From left to right: Ahmad Elgazzar, graduate student in chemical and biomolecular engineering at Rice; Haotian Wang, associate professor of chemical and biomolecular engineering, materials science and nanoengineering and chemistry at Rice; Shaoyun Hao, postdoctoral research associate in chemical and biomolecular engineering at Rice.

Electrochemical CO₂ reduction, or CO₂RR, is an emerging green technology that uses electricity, ideally from renewable sources, to transform climate-warming CO₂ into valuable products like carbon monoxide, ethylene or alcohols. These products can be further refined into fuels or used in industrial processes, potentially turning a major pollutant into a feedstock.

However, practical implementation has been hindered by poor system stability. One persistent issue is the accumulation of potassium bicarbonate salts in the gas flow channels, which occurs when potassium ions migrate from the anolyte across the anion exchange membrane to the cathode reaction zone and combine with CO₂ under high pH conditions.

"Salt precipitation blocks CO₂ transport and floods the gas diffusion electrode, which leads to performance failure," said Haotian Wang, associate professor of chemical and biomolecular engineering, materials science and nanoengineering and chemistry at Rice. "This typically happens within a few hundred hours, which is far from commercial viability."

To combat this, the Rice team tried an elegant twist on a standard procedure. Instead of using water to humidify the CO₂ gas input into the reactor, they bubbled the gas through an acid solution such as hydrochloric, formic or acetic acid.

The vapor from the acid is carried into the cathode reaction chamber in trace amounts, just enough to alter the local chemistry. Because the salts formed with these acids are much more soluble than potassium bicarbonate, they don’t crystallize and block the channels.

The effect was dramatic. In tests using a silver catalyst — a common benchmark for converting CO₂ to carbon monoxide — the system operated stably for over 2,000 hours in a lab-scale device and more than 4,500 hours in a 100-square-centimeter, scaled-up electrolyzer. In contrast, systems using standard water-humidified CO₂ failed after about 80 hours because of salt buildup.

Importantly, the acid-humidified method proved effective across multiple catalyst types, including zinc oxide, copper oxide and bismuth oxide, all of which are used to target different CO₂RR products. The researchers also demonstrated that the method could be scaled without compromising performance with large-scale devices maintaining energy efficiency and avoiding salt blockage over extended periods.

They observed minimal corrosion or damage to the anion exchange membranes that are typically sensitive to chloride by keeping the acid concentrations low. The approach was also shown to be compatible with commonly used membranes and materials, reinforcing its potential for integration into existing systems.

To observe salt formation in real time, the team used custom-built reactors with transparent flow plates. Under conventional water humidification, salt crystals began forming within 48 hours. With acid-humidified CO₂, however, no significant crystal accumulation was observed even after hundreds of hours, and any small deposits were eventually dissolved and carried out of the system.

"Using the traditional method of water-humidified CO₂ could lead to salt formation in the cathode gas flow channels," said Shaoyun Hao, postdoctoral research associate in chemical and biomolecular engineering at Rice. "We hypothesized — and confirmed — that acid vapor could dissolve the salt and convert the low solubility KHCO₃ into salt with higher solubility, thus shifting the solubility balance just enough to avoid clogging without affecting catalyst performance."

The work opens the door to more durable, scalable CO₂ electrolyzers, a critical need if the technology is to be deployed at industrial scales as part of carbon capture and utilization strategies. The simplicity of the approach, involving only small tweaks to existing humidification setups, means it can be adopted without significant redesigns or added costs.

"This is a major finding for CO₂ electrolysis," said Ahmad Elgazzar, graduate student in chemical and biomolecular engineering at Rice. "Our method addresses a long-standing obstacle with a low-cost, easily implementable solution. It’s a step toward making carbon utilization technologies more commercially viable and more sustainable."

This work was supported by the Robert A. Welch Foundation, Rice University, the National Science Foundation, and the David and Lucile Packard Foundation.

Subscribe to the newsletter

Daily decarbonization data and news delivered to your inbox

Follow the money flow of climate, technology, and energy investments to uncover new opportunities and jobs.

Latest issues

-

64 Carbon Projects Were Stuck. Texas Just Unlocked Them

Inside This Issue 🛢️ 64 Carbon Projects Were Stuck. Texas Just Unlocked Them ⚙️ In Ohio, Hydrogen Industry Presses on Despite Federal Uncertainty 🧲 Agami Zero Breaks Through With Magnetic Hydrogen...

-

This U.S. Plant Might Change Aviation Forever

In This Issue 🛫 A Georgia Plant Just Cracked Aviation's Fuel Puzzle 📉 CO2RE And ERM Release 2025 Update On Greenhouse Gas Removal Costs 🔗 Abatable Partners With BlueLayer To Streamline Corporate C...

-

Canada Just Made CCUS Way More Profitable

Inside This Issue 💼 Canada Unlocks EOR for Federal Tax Credits in Landmark Policy Shift 🚀 Carbontech Funding Opens as CDR Sector Pushes for Net-Zero Standard Revisions 💧 CHARBONE Confirms its Firs...

Company Announcements

-

Step strengthens Louisiana’s role in U.S. energy leadership and advances project finance process for biomass‑to‑fuel facility SACRAMENTO, Calif. & NEW ORLEANS -- DevvStream Corp. (Nasdaq: DEVS...

-

Climeworks Opens the World’s Largest Direct Air Capture Innovation Hub

Key takeaways: Climeworks launches the largest innovation center for Direct Air Capture, employing over 50 engineers in Zurich, Switzerland. The center is designed to reduce the cost and increase...

-

XCF Global Moves to Double SAF Production with New Rise Reno Expansion

Initial development completed at New Rise Reno 2, advancing XCF's second SAF production facility and positioning construction to begin in 2026. $300 million planned investment will double XCF'...

-

Carbon Capture Technology Relies on High-Performance CO2 Sensors

As the Global South's first Direct Air Capture (DAC) company, Octavia Carbon has commissioned the world's second DAC + geological storage plant. Harnessing Kenya's abundant renewable geothermal ene...