The discovery shows how atomic-scale distortions make fuel-cell catalysts stronger and more efficient for transport.

Researchers in the U.S. have developed a new catalyst that significantly improves the performance and durability of hydrogen fuel cells, potentially making them practical for heavy-duty vehicles and commercial fleets.

The research team at the Brookhaven National Laboratory, a U.S. Department of Energy (DOE) national research institution located in Upton, demonstrated that precise atomic engineering can extend catalyst lifetimes far beyond existing limits.

Tested under stringent conditions, the new material endured more than 90,000 operating cycles, which is the equivalent of 25,000 hours of continuous truck operation, while still outperforming current DOE targets.

>> In Other News: Cold Lake First Nations Raises Concerns Over Carbon Capture Project Potentially Being Put on Federal Fast-track

Xueru Zhao, PhD, a research associate in the lab’s chemistry division, stated that the results point to a practical pathway for developing fuel-cell systems capable of powering the trucks and buses of the future.

“Our catalyst not only meets immediate market needs but also lays the groundwork for widespread adoption in heavy-duty transportation,” Zhao said.

A next-gen catalyst

Fuel cells generate electricity by combining hydrogen and oxygen, releasing only water as a byproduct. This technology already works reliably for passenger cars.

Meanwhile, interest is growing in using them for heavy-duty vehicles like buses, freight trucks and long-haul transport. However, one of the biggest challenges is designing catalysts that are durable and efficient enough to meet the demands of such heavy-duty applications.

“Catalysts are the components that enable the chemistry at the electrodes inside a fuel cell,” Kotaro Sasaki, PhD, a Brookhaven chemist and one of the paper’s lead authors, stated.

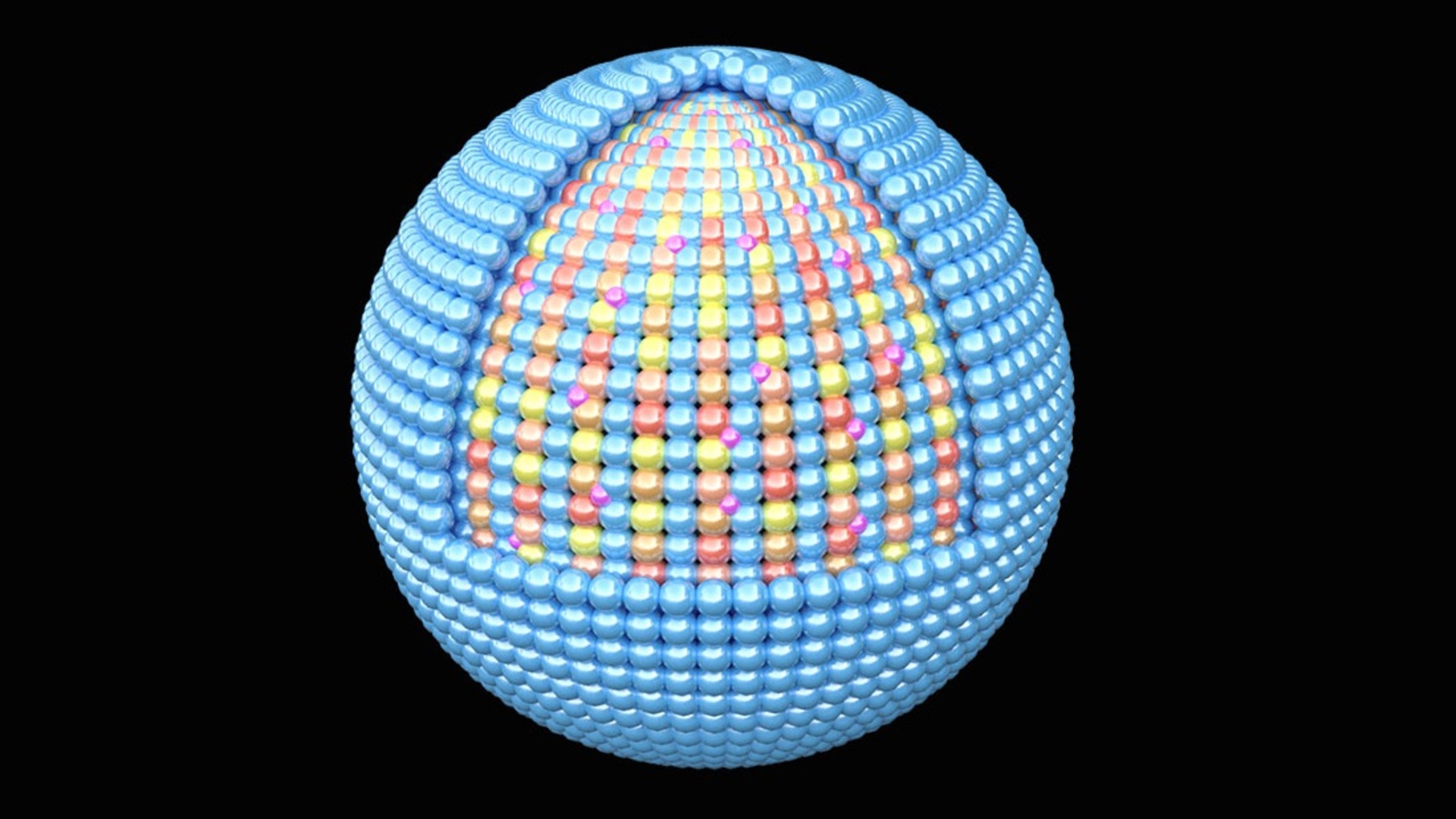

The Brookhaven National Laboratory revealed why a catalyst with a high-entropy intermetallic core, encapsulated by a single-layer shell of Platinum (Pt), shows promise for use in fuel cells for heavy-duty vehicles.

Sasaki revealed that these materials, often made of metals, bring the reacting chemicals together and lower the energy needed to drive the reaction.

“But the catalyst has to be able to perform this function over and over in challenging conditions, such as high heat or a harsh acidic environment,” he explained.

To tackle the challenge, the team came up with a nitrogen-doped catalyst from a finely tuned mix of platinum (Pt), cobalt (Co), nickel (Ni), iron (Fe) and copper (Cu), which is capable of sustaining high performance.

Record performance in tests

The scientists then protected the “high-entropy intermetallic” structure, named for its stable and ordered arrangement of multiple elements, with a platinum monolayer shell.

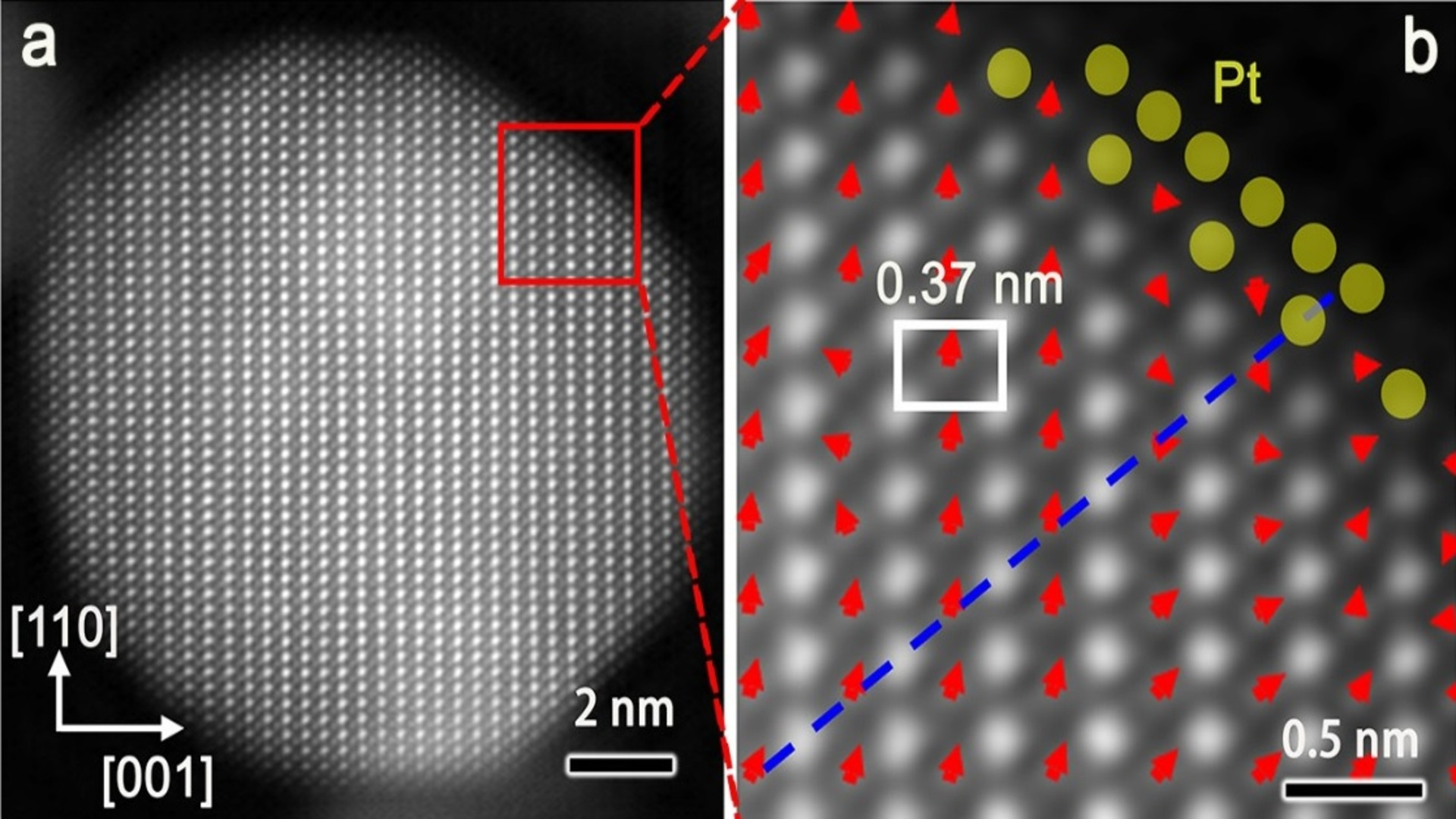

They zoomed in on the material at the atomic level using X-rays and microscopy and discovered that the new catalyst has tiny distortions in its atomic structure, that are partly caused by what they refer to as “sub-angstrom strain.”

These ultra-tiny distortions, which were smaller than the width of a single atom, turned out to be of great importance. They helped create strong bonds between the metals and nitrogen, improving both reactivity and resilience.

Under heavy-duty truck simulation, the new catalyst sustained over 90,000 cycles, equal to 25,000 hours of continuous use, while delivering current densities far above DOE targets.

The achievement involved close cooperation between Brookhaven’s chemistry, physics and nanomaterials divisions, as well as the use of DOE Office of Science user facilities.

“This is a clear example of how fundamental research at a national laboratory can have real-world impact,” Zhao concluded in a press release. “By uncovering the atomic-scale mechanisms that make this catalyst so effective, we’re opening the door to practical technologies that meet industry needs.”

The study has been published in the journal Nature Communications.

Subscribe to the newsletter

Daily decarbonization data and news delivered to your inbox

Follow the money flow of climate, technology, and energy investments to uncover new opportunities and jobs.

Latest issues

-

This $4.1M Deal Could Change Carbon Capture's Playbook

Inside This Issue 🗜️ CarbonQuest Lands $4.1M Alberta Deal on Gas Compressors 🛡️ CADO, 123Carbon, and Assure SAF Registry Join Forces to Tackle SAF Integrity Gaps ✈️ ISCC, OMV, and Airbus Partner t...

-

Can Koloma Crack Iowa's Billion-Year-Old Secret?

Inside This Issue ⛏️ Iowa's Hydrogen Rush: Can Koloma Strike Gold Before Rules Kick In? ✈️ Bentley Commits to Use 100% Sustainable Aviation Fuel for Car Airfreight 🌬️ Minister Parrott Provides Upd...

-

$47M Just Poured Into This SAF Producer

Inside This Issue 💰 LanzaJet Announces $47M in New Capital and First Close of Equity Round at $650M Pre-Money Valuation 🚢 Maersk's Ethanol Bet Could Reshape U.S. Fuel Markets 🪨 Canada Nickel and t...

Company Announcements

-

RCJY and Climeworks Deepen Partnership to Advance Large-scale Direct Air Capture in Saudi Arabia

Key takeaways: Under the guidance of the Ministry of Energy, the Royal Commission for Jubail and Yanbu and Climeworks have signed a Memorandum of Understanding to expand their collaboration on de...

-

CHARBONE Confirms New UHP Hydrogen Orders and its First UHP Oxygen Order in the United States

Brossard, Quebec, February 25, 2026 – CHARBONE CORPORATION (TSXV: CH; OTCQB: CHHYF; FSE: K47) (“CHARBONE” or the “Company”), a North American producer and distributor specializing in clean Ultra Hi...

-

Climeworks Establishes Canadian Headquarters in Calgary

Calgary, Alberta, February 20, 2026 — Climeworks, a global leader in commercial carbon removal, has established its Canadian headquarters at Calgary’s ETC, one of Alberta’s leading hubs where start...

-

MIAMI, Feb. 24, 2026 /CNW/ - Power Sustainable Infrastructure Credit ("PSIC") recently closed an $85M senior secured financing for Sagepoint Energy ("Sagepoint"), a vertically integrated renewable ...